Technical Facts

Producing capabilities

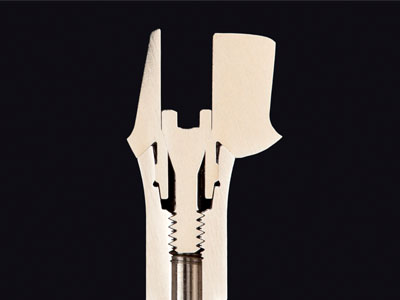

TURNING AND MILLING PARTS

We have a huge expertise on turning and milling activities that started back in 1947, and today we focus all that knowledge on our dental implant parts production.

At the end of 2016 we were producing more than 1 million parts per year.

Machinery: we rely 100% of our production on Swiss and Japanese CNC machinery since 1994. Today we have a wide park of Swiss Tornos and Okuma CNC turning machines that increase every year thanks to our permanent growing production.

All machines are optimised for medical production and enjoy a sublime care from our staff to keep their accuracy and precision along all its lifetime.

Materials: we use to work in all kind of sanitary materials such as:

- Titanium grade 5

- Titanium grade 4

- Titanium grade 2

- Cobalt Chrome micro-melt and nickel free

- PEEK (Polyether Ether Ketone)

- POM (PolyOxy Methylene)

- PMMA (Polymethil Methacrilate)

- Supplied by the customer

All materials come from the better suppliers, certified and with casting / producing certificates.

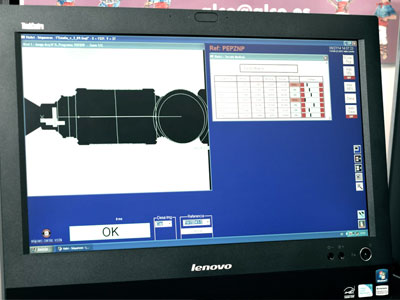

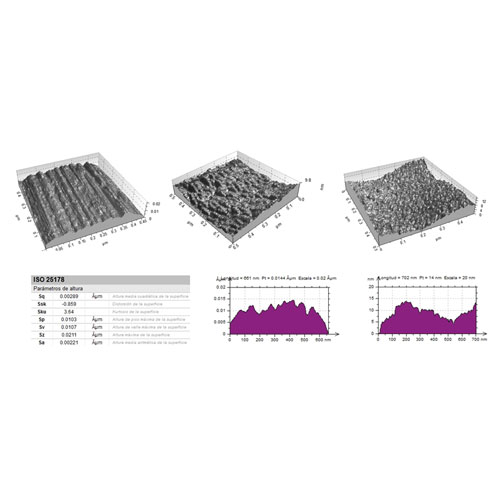

Quality Assurance

Quality is without compromise. That’s the main rule along all our procedures after 70 years of experience.

In Terrats Medical we apply the highest standards in quality control under the framework of ISO 9001 and ISO 13485 and CE marking up to class II.

We listen to customers’ designs, tolerances, risk definitions and all special needs each product have.

Thanks to our expertise on dental implant products manufacturing we know very well where to focus and apply the maximum attention and quality requirements.

Regulatory Certificates

Terrats Medical is ISO 9001 certified since 1998 and ISO 13485 certified since 2010 as well as CE validated producer since 2010 too.

On top of this we have achieved also the CMDCAS Canadian Regulatory certificate as well as got the 510K certification on many of our products by the FDA.

We can apply this achievements in OEM / OBL or be the partner of our customer to get their own.

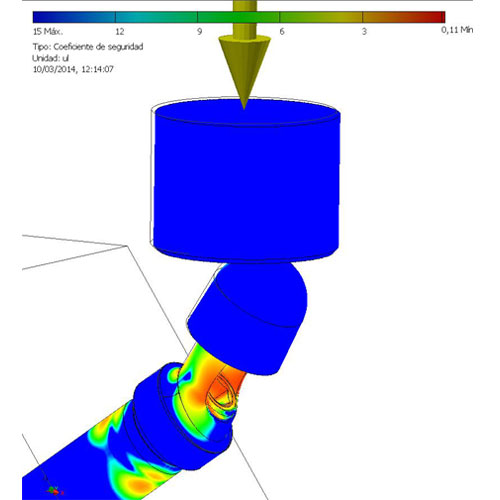

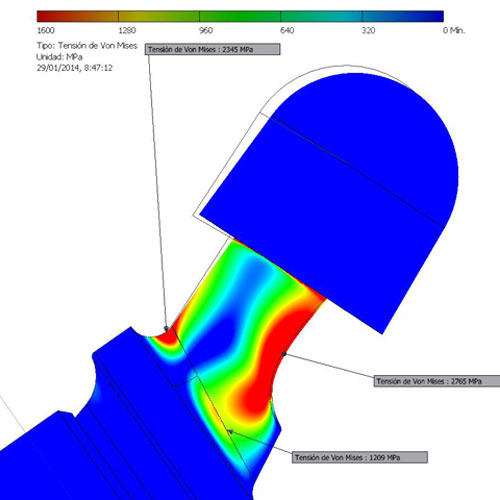

Product Testing

We have our own set of machinery to conduct tests and we work with several partners to get the necessary 3rd certificate parties tests to go through the regulatory requirements.

We apply also the latest technology in Finite Element Analysis simulation for our and customers’ designs. This is a very valuable first hint on where to improve any solution to make it more reliable and more cost efficient.